FLIGHT TIME

Powerful sailing machine Sea Eagle is right at home in the land of the original seafarers

Sea Eagle’s 81 metres of lean aluminium were designed in pursuit of world-roaming comfort. Marilyn Mower learns how Royal Huisman helped an owner’s dream take wing

TIM MCKENNA

When Dutch builder Royal Huisman delivered Sea Eagle, it noted that the schooner was its longest yacht yet, the ninth largest sailing yacht in service and the world’s second-largest all-aluminium sailing yacht. It wasn’t that long ago that building such a large bluewater sailing yacht solely in aluminium would have raised many an eyebrow. But nearly 60 years of aluminium yacht-building experience and the ability to create limitless virtual models for computer testing led to an optimal Alustar hull structure for the perfect fast passagemaker.

Sea Eagle – she carried the Roman numeral II in her name when launched in 2020 – promptly left northern Europe for the Mediterranean and then the Pacific, beginning the planned circumnavigation for her commissioning owner, Taiwanese owner Dr Samuel Yin. He had developed the brief for this boat as he cruised far and wide on his first Royal Huisman, a 43-metre by the same name. That Sea Eagle, now Ravenger, was a performance sloop. For his next yacht, he sought more comfort, more amenities for guests and crew, and more range so he could see as much of the world as possible under sail.

TIM MCKENNA

TIM MCKENNA

Although he was originally tempted to follow the majestic look of another Royal Huisman, Athena, the modern aesthetic of a plumb bow and zen-like simplicity won out. He referred to his dream as, “a true sailor’s yacht – practical, powerful and easy to manage”. The result is nearly twice the length and five times the volume of her predecessor. Sea Eagle’s long waterline and powerful Panamax schooner rig certainly can deliver distance, as she comfortably ticks 21.5 knots in a moderate breeze.

As for ease of management, despite a massive sail area (2,580 square metres upwind), all three mainsails can easily be hoisted or lowered at once – taking no more time than required for a sloop half the size. She can add another 972 square metres of sail area for offwind sailing. And off soundings, too, apparently, as the yacht has logged more than 45,000 nautical miles to date.

YACHTING IMAGE

YACHTING IMAGE

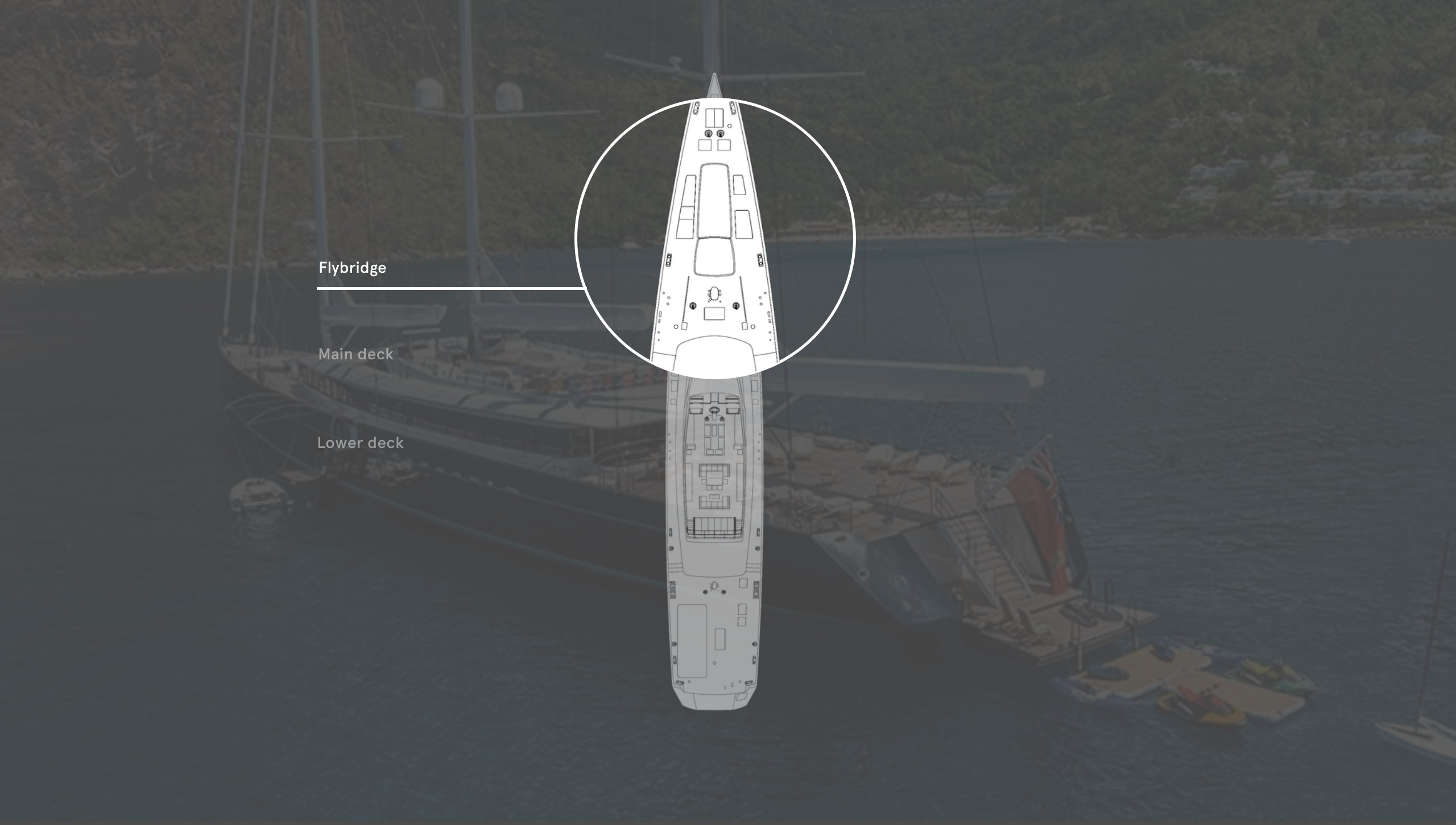

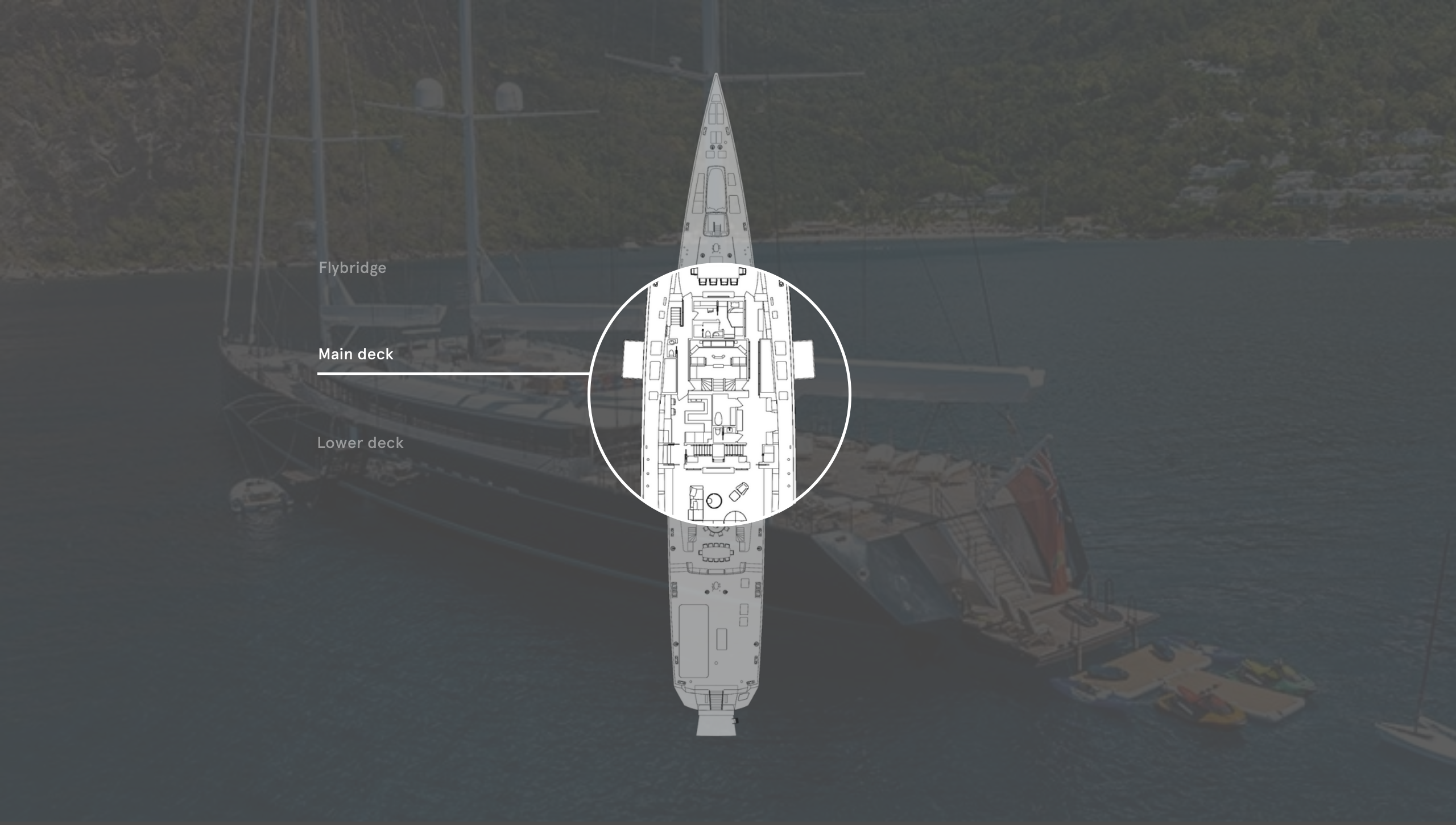

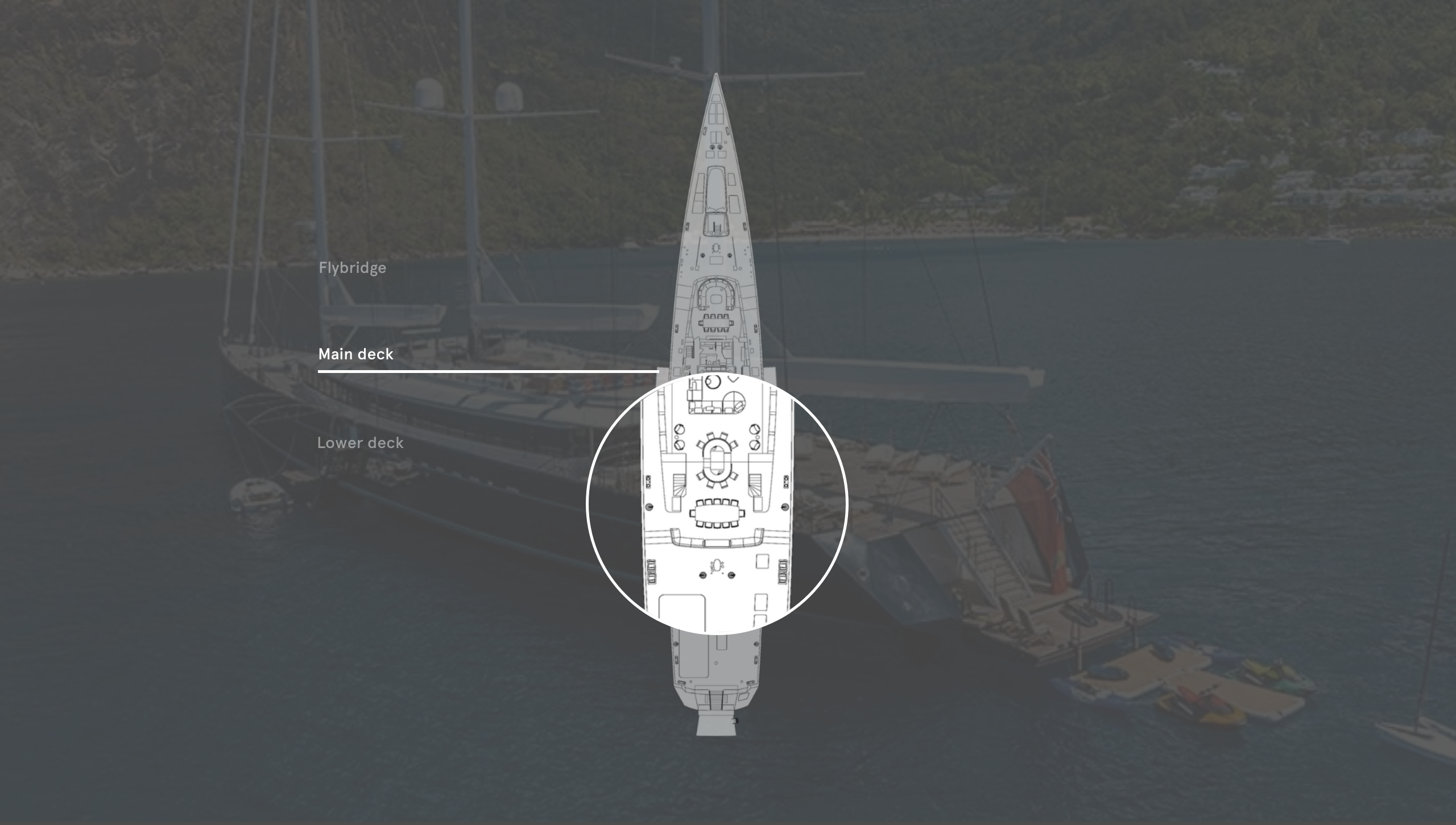

The flybridge and main aft deck were designed to be the primary social spaces. Flexibility is ensured with high-low tables on the flybridge and all loose furniture on the main deck

Dykstra Naval Architects reviewed existing tank test results to figure out the optimal waterline length between the plumb bow and full transom, and the transition from a U-shape forward to flatter sections aft. Next, computer simulations, including CFD and scale model testing, minimised wetted surface drag of the fin keel. Models produced from this data were tested at Delft University of Technology’s towing tank.

The result predicted excellent handling, seakeeping and faster crossings in comfort. “Due to the higher stability from spreading the sail area across three masts and her six-metre draught, the yacht sails with less heel, greatly improving the comfort on board,” says Erik Wassen of Dykstra Naval Architects.

TIM MCKENNA Despite a massive sail area, all three mainsails can easily be hoisted or lowered at once - taking no more time than required for a sloop half the size

TIM MCKENNA Despite a massive sail area, all three mainsails can easily be hoisted or lowered at once - taking no more time than required for a sloop half the size

The relatively simple rig and sailplan were refined by testing at the Wolfson Unit wind tunnel. It is managed by Rondal’s Integrated Sail Handling System, which interfaces spars, rigging, 34 winches and sailing hardware. The largest winches – for the yankee, staysail sheets and mizzen sheet runners – are capable of 18 tonnes pulling load. Although the total sail area is large, none of the sails is larger than any sail on a 60-metre sloop or ketch, so it’s not unknown territory.

The three carbon-fibre masts, each a little taller from bow to stern, have a maximum air draught of 61 metres to negotiate the Panama Canal. Like all Rondal carbon masts, Sea Eagle’s sticks are one piece. High modulus carbon fibres run continuously from masthead to heel. Carbo-Link standing rod rigging keeps it all in place. The carbon-fibre rollerfurling booms, captive reel and drum winches and flush deck hatches were also from Rondal.

Dykstra Naval Architects reviewed existing tank test results to figure out the optimal waterline length between the plumb bow and full transom, and the transition from a U-shape forward to flatter sections aft. Next, computer simulations, including CFD and scale model testing, minimised wetted surface drag of the fin keel. Models produced from this data were tested at Delft University of Technology’s towing tank.

The result predicted excellent handling, seakeeping and faster crossings in comfort. “Due to the higher stability from spreading the sail area across three masts and her six-metre draught, the yacht sails with less heel, greatly improving the comfort on board,” says Erik Wassen of Dykstra Naval Architects.

TIM MCKENNA Despite a massive sail area, all three mainsails can easily be hoisted or lowered at once - taking no more time than required for a sloop half the size

TIM MCKENNA Despite a massive sail area, all three mainsails can easily be hoisted or lowered at once - taking no more time than required for a sloop half the size

The relatively simple rig and sailplan were refined by testing at the Wolfson Unit wind tunnel. It is managed by Rondal’s Integrated Sail Handling System, which interfaces spars, rigging, 34 winches and sailing hardware. The largest winches – for the yankee, staysail sheets and mizzen sheet runners – are capable of 18 tonnes pulling load. Although the total sail area is large, none of the sails is larger than any sail on a 60-metre sloop or ketch, so it’s not unknown territory.

TIM MCKENNA

TIM MCKENNA

The three carbon-fibre masts, each a little taller from bow to stern, have a maximum air draught of 61 metres to negotiate the Panama Canal. Like all Rondal carbon masts, Sea Eagle’s sticks are one piece. High modulus carbon fibres run continuously from masthead to heel. Carbo-Link standing rod rigging keeps it all in place. The carbon-fibre rollerfurling booms, captive reel and drum winches and flush deck hatches were also from Rondal.

The seating arrangement was changed and high-low tables were added for an optional al fresco dining spot up top

Mark Whiteley of Mark Whiteley Design summarised key aspects of the exterior co-creation with Dykstra: “The essence of the yacht’s appeal is illustrated by long, uninterrupted lines of glass, a subtle sweep of superstructure and a blister to enclose the bridge. The overall effect gives the superstructure a curved tension that draws the eye from bow to stern.”

The half-deck rise to the bridge is “space efficient”, says Whiteley, with negligible impact on either deck. The yacht’s nearly flat sheer line is in keeping with the owner’s request for a main deck without steps from the exterior dining space right through the large main saloon to the forward dining saloon.

Sea Eagle’s superstructure looks deceptively low as it starts 700 millimetres below the height of the bulwarks. It is a largely rigid structure made principally from laminated glass topped with an all-aluminium flybridge. In a seaway, it will flex differently than the longitudinally stiffened hull.

The solution is a sophisticated adhesive developed by aerospace specialists and classification officials especially for this project. It absorbs up to two centimetres of flex between the mullions and the top deck structure, while also providing a permanently secure and weathertight bond. This allows the look of a continuous darkly tinted glass surface outside, while the interior windows are framed in substantial leather-wrapped mullions obscuring necessary structure. It was, says naval architect Wassen, the most complex part of the project.

TIM MCKENNA

TIM MCKENNA

TIM MCKENNA

TIM MCKENNA

The main mast features a push-button crow’s nest that provides guests with stunning “sea eagle” view

Wassen is also responsible for the smart-looking chine that runs from the bow about two-thirds down the length. “I thought a four-metre-high, 80-metre flat panel painted dark blue would be uninteresting,” he says. “The chine, or knuckle, gives it a bit more of an aggressive look and also [brings] a little more width at deck level, which [is] particularly useful in the area of the foremast.”

YACHTING IMAGE

YACHTING IMAGE

The owner referred to his dream boat as “a true sailor’s yacht – practical, powerful and easy to manage”

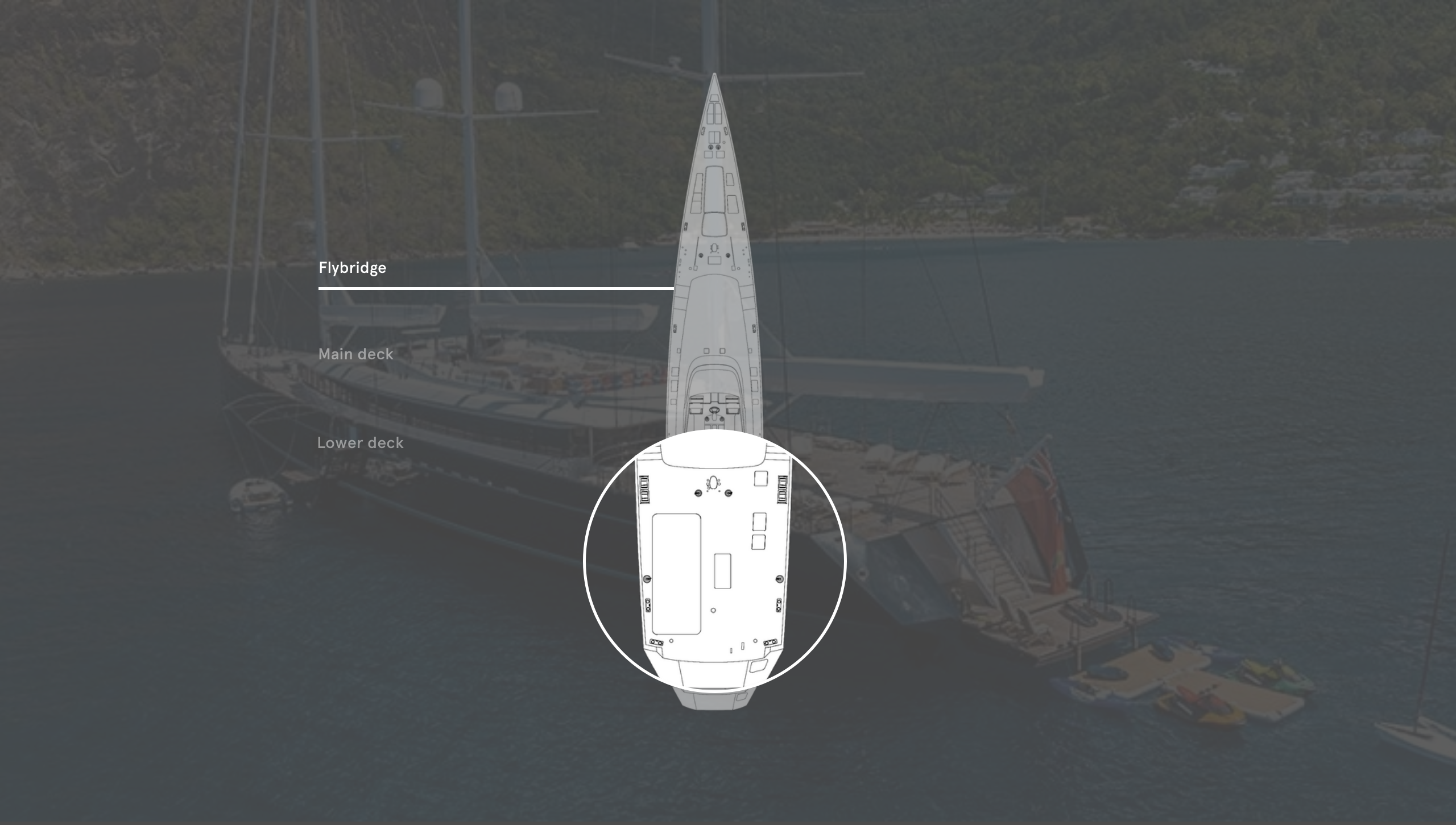

He matched it with a similar knuckle at the edge of the superstructure and the crew’s deckhouse, and gave matching angles to the booms and the steering pedestals. Without a steering cockpit to contend with, the aft deck expanse is open for use as a sundeck, al fresco gym or, at night, a cinema with the screen secured by the mizzen boom and backstays. From here, exceptionally wide and comfortable steps lead to the swim platform where watersports toys are deployed from an adjacent lazarette.

YACHTING IMAGE

YACHTING IMAGE

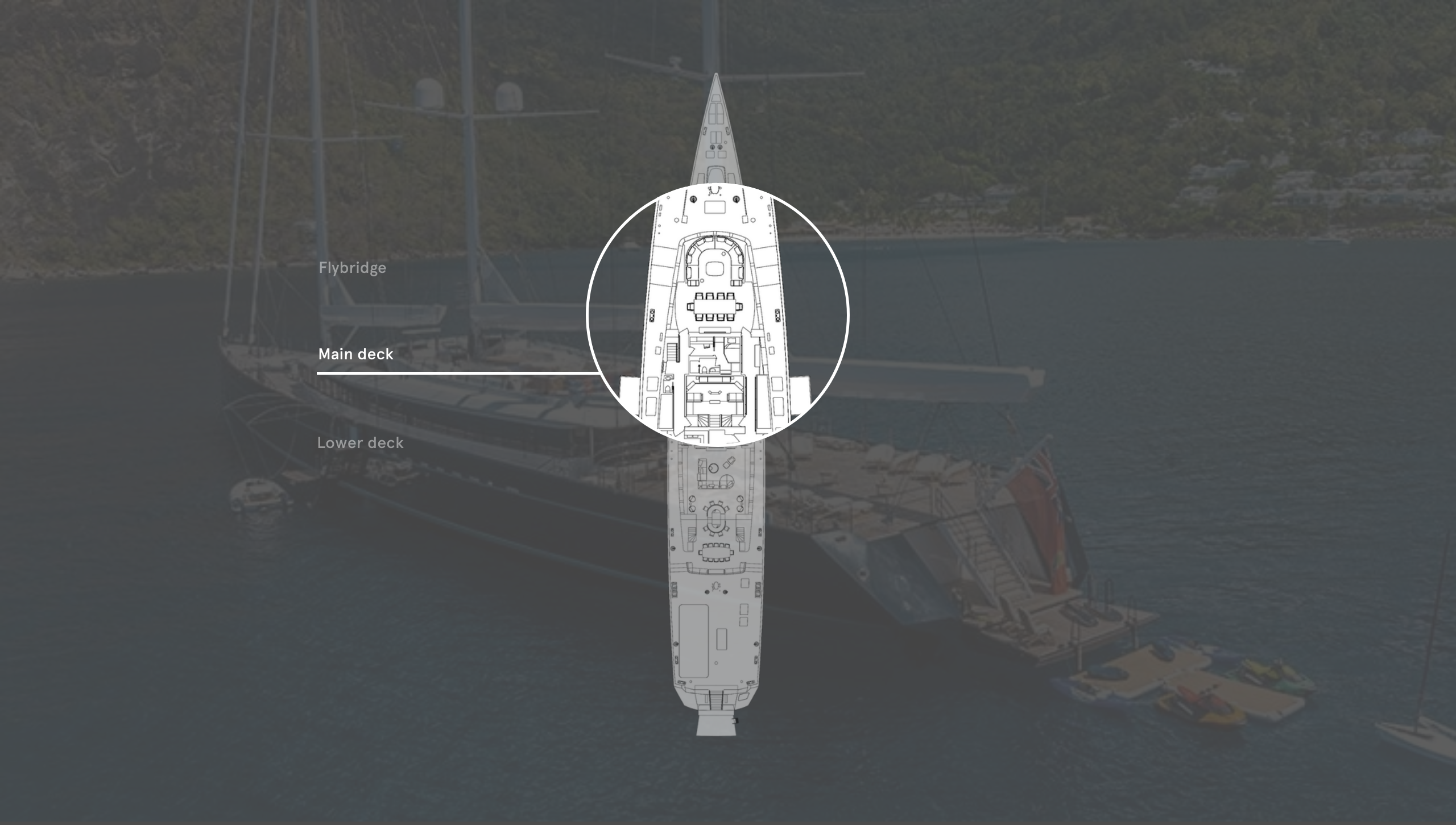

Going forward from the aft deck, down three steps, is the outdoor dining area protected by a long overhang. A simple teak table on a stainless-steel base seats 10. It is flanked on one side by an enormous semicircular sofa and, on the other, by half of the indoor/outdoor bar. This interesting ellipse feature has one U-shaped section on the aft deck and the other in the main saloon.

Whiteley says the owner saw it on Maltese Falcon and it appealed to him as a space where a smaller group of guests could hang out. Sliding-glass partitions and doors that hide away in bulkhead structures can separate the two spaces with no threshold trip hazard in between. Staircases on either side lead up to the flybridge deck. Inside, the casual aft saloon has generous seating that faces a television screen.

TEAM SEA EAGLE

TEAM SEA EAGLE

TEAM SEA EAGLE

TEAM SEA EAGLE

The main saloon has new decor to appeal to charterers; the joinery in the bedrooms, made of engineered hardwood veneer from Alpi, is stained to a walnut finish and the grain is purposefully oriented horizontally

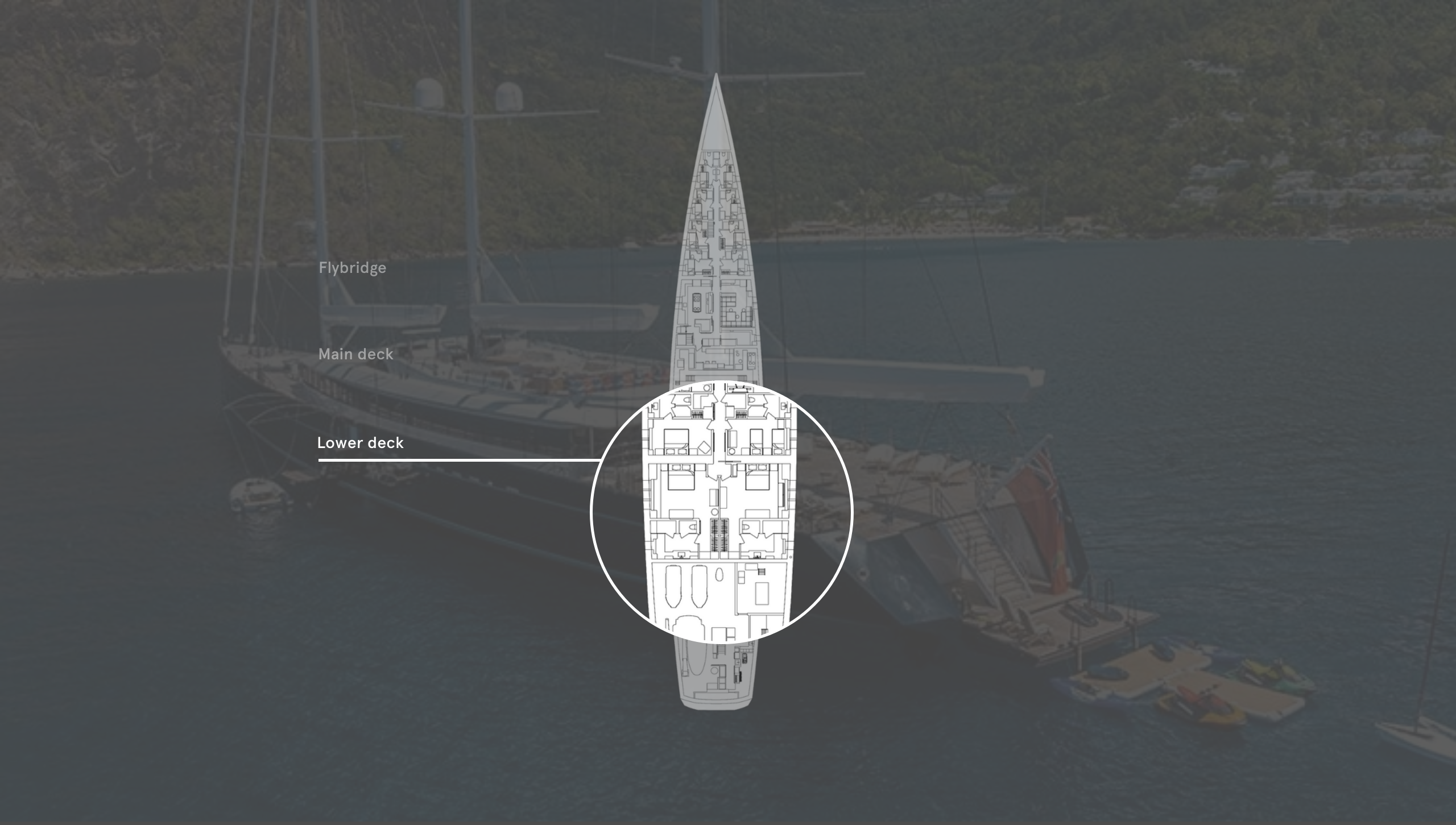

Sea Eagle has a symmetrical arrangement throughout with crew circulation on port and guests on starboard. The twinning of doors and stairways gives a pleasing balance to the spaces. On the guest side, a hall leads forward from the saloon, past steps to the pilothouse, to another unique feature – a forward dining saloon with adjacent seating. This arrangement recalls motor yachts of the 1960s and 70s that featured dining forward with views over the bow.

Later yachts, primarily those for the US market, combined this with the galley to create the informal country kitchen. But there is nothing informal about this space; it’s elegant with dining for up to 14 opposite wraparound seating under panoramic windows. While there is a substantial service pantry on port, the galley is on the lower deck, adjacent to a sizable crew mess.

TEAM SEA EAGLE

TEAM SEA EAGLE

Designer Mark Whiteley helped make the layout and furnishings a more amenable for a wider audience

When it was decided in 2022 that Sea Eagle would be made available for charter, Whiteley helped make the layout and furnishings a more amenable for a wider audience. In the forward lounge, a pair of loveseats and a small sofa at right angles have been replaced by enough seating to accommodate the entire guest complement at once. The main saloon also saw an update, replacing a U-shaped sofa with a low, sleek sectional.

Below deck, one of the six guest cabins was upgraded from twins to a double berth. Adjoining the guest cabins on the lower deck is a gym, an asset that bolsters her charter credentials. Whiteley says the subtle changes in fabric selections and the addition of new area rugs bring an added warmth to the rooms that he quite likes. The artwork they selected, simply matted black and white photos, perfectly accompanies the walnut and wenge background.

Simplicity extends to the bare white oak floors from Schotten & Hansen that are found on both decks. It’s the same flooring chosen for the first Sea Eagle except that, now, two large, fluffy Minotti silver Alps rugs soften the seating areas of the two saloons.

TEAM SEA EAGLE

TEAM SEA EAGLE

YACHTING IMAGE

YACHTING IMAGE

YACHTING IMAGE

YACHTING IMAGE

TEAM SEA EAGLE

TEAM SEA EAGLE

The artwork selected, simply matted black and white photos, perfectly accompanies the walnut and wenge background. The simplicity extends to the bare white oak floors

Whiteley chose an engineered hardwood veneer from Alpi, stained to a walnut finish, for the joinery and built-in furniture. He oriented the grain to run horizontally to emphasise the linear theme of the boat. “Typically, and especially on a sailboat, you orient the grain vertically to add a sense of height,” says Whiteley. “I did this to emphasise length and the single level of the main deck. The only other timber is wenge, and that appears as horizontal banding.”

The flybridge provides an exciting 360-degree view since there is no superstructure forward and the outdoor helm station is low. During the pre-charter facelift, the seating arrangement was changed and high-low tables were added for an optional al fresco dining spot up top.

YACHTING IMAGE This pre-fit decor and furniture was replaced with Italian furniture, like Minotti sofas, lending the interior a chic and contemporary feel

YACHTING IMAGE This pre-fit decor and furniture was replaced with Italian furniture, like Minotti sofas, lending the interior a chic and contemporary feel

In terms of energy generation and management, Sea Eagle includes advanced technologies pioneered by Royal Huisman that have already shown efficiency and reliability on other projects. Electrical and hydraulic power comes mainly from the twin generators. In addition, there is a hydraulic take-off from each main engine and peak shaving from the powerful battery bank. This offers a massive amount of hydraulic capacity – more than enough to hoist fore, main and mizzen sails at once. A main switchboard with power management and paralleling systems enables all sources and consumers of power to be handled most efficiently.

In her new role, Sea Eagle has spent the summer cruising the Baltic, taking guests to Scandinavian cities and sampling storybook scenery. This powerful sailing machine seemed right at home in the land of the original seafarers.

First published in the January 2024 issue of BOAT International. Get this magazine sent straight to your door, or subscribe and never miss an issue.

When the 5m crew tender is offloaded, its bay becomes an outdoor crew area

The main deck aft can be set up as an al fresco cinema

A formal dining saloon features views over the bow

Access to the side decks and lower deck is via foldout platforms to port and starboard

An inside/outside bar straddles the aft deck and saloon

A portside guest cabin changed from twins to a double berth

LOA 81m | Engines |

LWL 78m | Generators |

Beam 12m | Speed under power (max/cruise) 22/12.5 knots |

Draught 6m | Downwind sail area |

Mast and boom | Sails Doyle |

Gross tonnage | Owners/guests 12 |

Fuel capacity | Crew 14 |

Freshwater capacity | Construction |

Naval architecture | Classification |

Exterior styling | Builder/year |

Interior design | For charter |